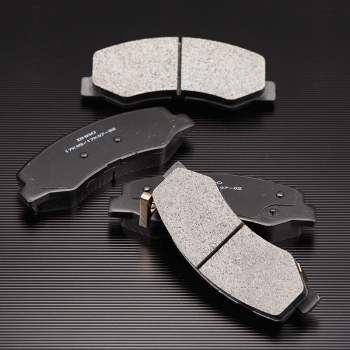

BRAKE PAD

Brake pad materials are classified as the selection rate of used materials. They fall into three categories, namely, semi-metallic / low-steel / nonsteel, based on their metal contents.

Semi-metallic brake pads are made of 50% metal materials. Product features are determined by metal properties.

Semi-metal brake pads are strong against abrasion and have a higher heat transfer rate. However, their friction coefficient is low, and these pads are weak against corrosion.

Low-steel brake pads are made of 30% metal materials. Low friction coefficient and corrosive property have been improved, and manufacturing costs are reduced by reducing the metal content.

Nonsteel brake pads are made of nonsteel materials. This type does not absorb heat as well as semi-metal brake pads which can increase the temperature of the brake system because of its nonmetallic properties.

We mostly manufacture low-steel brake pads.

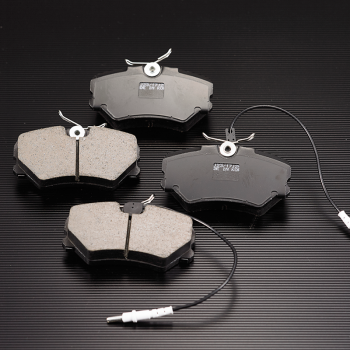

However, we have only adopted the advantages of low-steel and nonsteel brake pads by minimizing metal contents. We also design our products based on high friction coefficient and thermal stability to ensure that they can work under various service conditions.

D Only Automotive’s brake pads are high functional and eco-friendly premium products made from high-functional materials, including Kevlar and titanium and fine ceramics, and excluding six heavy metals and harmful chemical substances.